Cages design

The

main requirements to a cage:

-

to

separate antifriction pieces so that

heat

release would be minimum;

-

to keep pieces at equal distance from each other to distribute

the load

among

them evenly;

-

to

keep rolling element from fallout in

separable and support-rotary bearings;

-

to

transfer

rolling

elements

(balls and

rollers)

to

the bearing area without a

load;

Bearings cages are divided into: pressed metal cage and massive cages. The less weight of pressed sheet metal cages is an advantage over massive metal cages.

Pressed

cages use to a less extent the

space

between

the

inner and outer rings, so grease penetrates into bearings easier. Since

the instrument to stamp cages is the most expensive, such types of cages

are used in mass

production of bearings. Massive metal and textolite

cages are made by methods of machining. Massive metal cages are applied

first of all in the production of large size bearings which are manufactured

in small

lots.

Massive

metal cages are also applied in case of stringent

requirements to cages hardness as

well as at high temperature in the assembly unit. In order

to provide smooth operation

of bearings with massive cages, the cages are based

by

the rib of one of the rings.

Such

types of cages are most of all applied in high-speed bearings. In this

case they are manufactured from light materials, such as light metal and

textolite to reduce inertial loads.

Massive

polyamide cages are produced by die casting. First

of all they are intended for large-scaled production. With the help

of die casting, a special form of the cage can be made that to a great

extent promotes creating a bearing with high

load carrying capacity.

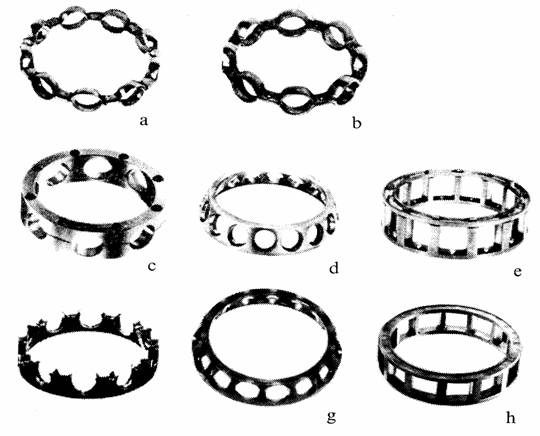

You can see some examples of antifriction bearing cages design:

-

pressed steel cages for radial boll bearing: ribbon type

clincehed cages (a); ribbon type riveted cages (b) and cages

with upset bars;

-

massive brass cage with rivets for radial ball bearings

(c);

-

massive window type brass cages for angular-contact ball

bearings(d);

-

massive brass cage with cage bars (on rivets) for radial roller

bearings (e);

-

massive cage made of glass-fibre

reinforsed polyamid

for

single-row radial ball bearings (f);

-

massive window type cage made of glass-fibre

reinforsed polyamid for angular-contact ball bearings (g);

-

massive window type cage made of glass-fibre

reinforsed polyamid for single-row radial roller bearings (h);